Risk Based Inspection (API RP 580/581)

In the past, inspection of pressurized equipment was determined from custom industry practice based on prescriptive codes, Operator experience and health and safety legislation. The inspection frequency, methods employed and locations examined were determined by the type of equipment with little consideration given to its age, specific duty or likely damage.

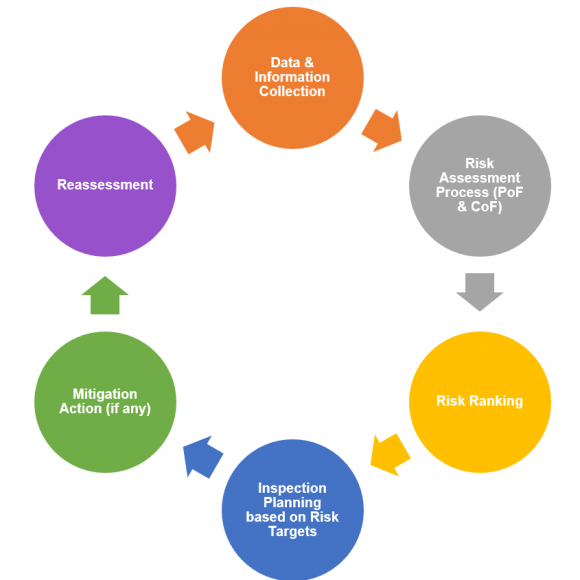

Risk based inspection is the process of developing a scheme of inspection based on knowledge of the risk of failure. Risk analysis process is the combination of an assessment of the likelihood (probability) of failure due to flaws damage, deterioration or degradation with an assessment of the consequences of such failure. A suitable inspection scheme will deploy techniques at a frequency that provides adequate confidence about the condition, taking account of the damage mechanisms and the reliability of the inspection techniques used.

Risk Based Inspection Process:

Some of the major benefits realized from the RBI implementations:

- Better understanding of the risks involved in the operation of plant/process unit and risk management through inspection and other mitigation actions.

- Extends the life of plant by identifying what may go wrong and how to prevent it by reducing the risk of integrity failure, which invariably shortens the life of the plant.

- Reduction in turnaround duration by elimination of unnecessary inspection activities, thus reducing risk of accidents during turnaround activities.

- Optimization of inspection and maintenance costs by allocating resources to high-risk items where they are really needed, substitution of intrusive inspection with online or non-intrusive inspection techniques, replacing more frequent inspections less effective with more effective inspection.

- Establishing Integrity Operating Windows.

ARAIS team has years of practical experience in implementing RBI programs for various facilities around the globe.

Our RBI turnkey consulting services include:

- Development of RBI procedure for specific project or facility operations.

- Implementation of RBI program using:

- Qualitative, Semi-Quantitative and Quantitative RBI approaches based on the API RP 581 for Pressure Vessel, Piping, Storage Tank, Pressure Relief Device, and Heat Exchanger Tube Bundle.

- Qualitative RBI (Scoring based) approach for Atmospheric Storage Tank as per EEMUA 159 5th Edition.

- “The ARKSoft” Risk Assessment Platform as part of our digital solution.

- RBI program gap assessment which includes review of your existing program and help you to identify areas of improvement that will aid in the integration and sustainability of your RBI program.

We Provide the Best Service in Industry

We serve with utmost sincerity, honesty, within deadlines, pure innovation, planning, strategy, and out-of-box solutions.